Manufacturing has always been at the heart of industrial growth. However, with the rapid rise of innovative technologies, traditional manufacturing methods are being challenged. In Qatar, 3D printing is making waves across multiple sectors, reshaping the way products are designed, developed, and delivered. From reducing costs to enhancing customization, 3D printing is proving to be a game-changer for the country’s manufacturing industry.

A Shift Towards Advanced Manufacturing

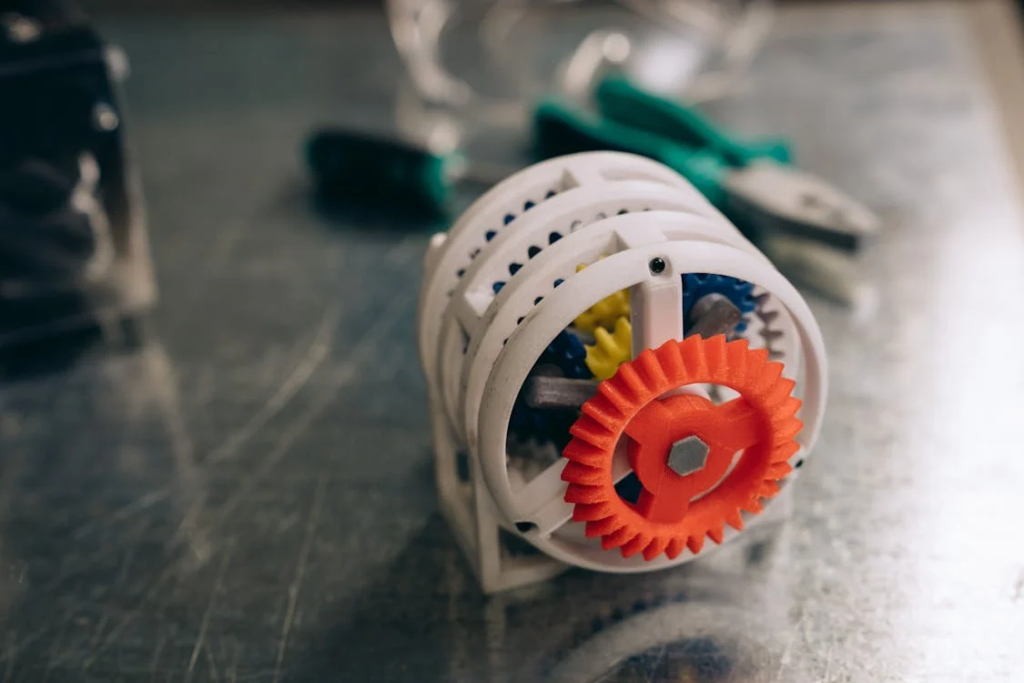

Qatar has been investing heavily in advanced technologies, aiming to become a hub for innovation. 3D printing, or additive manufacturing, has emerged as a key technology driving this shift. Unlike conventional manufacturing, which typically involves cutting or molding materials, 3D printing builds objects layer by layer from digital designs. This offers several advantages, including speed, precision, and the ability to create complex structures that traditional methods may struggle with.

As the country positions itself to diversify its economy beyond oil and gas, 3D printing Qatar is playing a significant role in shaping the future of the country’s manufacturing sector.

Cost Efficiency and Resource Optimization

One of the primary benefits of 3D printing is its potential for cost savings. In traditional manufacturing, producing custom parts or prototypes often requires expensive molds, tooling, and significant material waste. 3D printing eliminates the need for molds and reduces waste by using only the required amount of material.

For manufacturers in Qatar, this means not only lower production costs but also faster turnaround times. Prototypes and small batches can be created quickly and modified easily without the high costs of retooling or setting up new production lines. This is particularly valuable for sectors such as aerospace, automotive, and healthcare, where customization and precision are critical.

Customization and Innovation

3D printing allows for unprecedented levels of customization. Unlike mass production, where every item is identical, 3D printing enables manufacturers to create bespoke products tailored to specific customer needs. This is a huge advantage for companies in Qatar that are looking to offer personalized solutions to their clients.

For instance, in the healthcare industry, 3D printing is being used to create custom prosthetics, surgical guides, and even medical implants that are tailored to individual patients. Similarly, in architecture and construction, 3D printing is enabling the creation of unique building elements and intricate designs that were previously difficult to achieve.

This ability to customize products has opened up new avenues for innovation, pushing the boundaries of what’s possible in manufacturing.

Speeding Up Time-to-Market

In the competitive world of manufacturing, speed is often the difference between success and failure. Traditional manufacturing methods can be time-consuming, especially when it comes to designing, prototyping, and testing new products. 3D printing significantly reduces these lead times.

Manufacturers in Qatar are now able to bring products to market faster than ever before. With 3D printing, digital designs can be turned into physical objects within hours, allowing companies to quickly iterate, test, and refine their products. This rapid prototyping capability is especially beneficial for startups and SMEs looking to disrupt markets with innovative products.

Driving Sustainability in Manufacturing

Sustainability has become a global priority, and Qatar is no exception. As part of its Vision 2030 initiative, the country is focused on reducing its environmental footprint and promoting sustainable development across various sectors. 3D printing aligns with these goals by offering more sustainable manufacturing processes.

Unlike traditional methods that generate a significant amount of material waste, 3D printing uses only what is necessary to create the final product. This not only reduces waste but also lowers energy consumption, as fewer resources are required to produce each item. Additionally, local production through 3D printing minimizes the need for transportation and reduces the carbon footprint associated with importing goods.

By adopting 3D printing, Qatar is taking steps toward more eco-friendly manufacturing practices, which will play a crucial role in the country’s efforts to achieve its sustainability objectives.

Challenges and Opportunities Ahead

While 3D printing offers many advantages, there are still challenges to overcome. The technology is relatively new in Qatar, and there is a learning curve for companies to fully integrate 3D printing into their existing manufacturing processes. Additionally, the high initial investment in 3D printers and materials can be a barrier for smaller businesses.

However, the opportunities far outweigh the challenges. As the technology continues to advance, costs are expected to decrease, making 3D printing more accessible to a broader range of industries. With the right support and investment, Qatar is well-positioned to become a leader in 3D printing and advanced manufacturing in the region.

Conclusion

3D printing is reshaping the manufacturing landscape in Qatar, offering businesses new ways to innovate, reduce costs, and improve sustainability. From rapid prototyping to custom products, the technology is driving efficiency and unlocking new possibilities for manufacturers across various industries.

As 3D printing becomes more mainstream, its role in Qatar’s manufacturing sector will only continue to grow, helping the country achieve its ambitious economic diversification goals. The future of manufacturing in Qatar is not just about producing more—it’s about producing smarter, faster, and more sustainably. And with 3D printing at the forefront of this transformation, the future looks bright.